Business Intelligence will have the biggest impact on the logistics sector and this technology will be deployed on a large scale by logistics service providers in the short term. This is not surprising when we look at the growing complexity in the supply chain. Because when it goes wrong in the chain somewhere, the margin quickly deteriorates. And that can bring along major costs. Moreover, understanding data is not only useful for optimizing your own business processes. The need for data also increases for your clients. For example, what are their fast moving goods and how can they finetune their production process in a better way? Can you not answer these questions for them? Then you are at risk of losing customers and partners.

Because of digitalization and technology, we are now in the so-called “fourth industrial revolution”. And you know, revolution demands change!

Key performance indicators logistics

Alright, you are convinced: you want to integrate data analyzes into your activities. That is a good start. But what now? Boltrics has conducted extensive research among its customers in the past. From this research, the 6 most important KPIs for logistics service providers came forward. So, you already know which key performance indicators are important. But how do you interpret them and what are good values? In this blog I will go deeper into the first of the six KPIs: the occupancy rate.

The ideal occupancy rate

It is already a while ago, but Tompkins (1998) stated in his Warehouse Management Handbook that an occupancy rate higher than 80% negatively affects your warehouse’s efficiency. From that percentage, it takes more time to find a storage location and the slow movers will lie between the fast movers. Order pickers will be in each other’s way and the productivity of the warehouse gets compromised. The maximum occupancy should be around 85 to 90%. This way, there is always room for an unexpected urgent order. An occupancy rate below 80% means that more than 20% of the warehouse is not in use. These unused places only cost money. But what does a (pallet) place actually cost?

Occupancy rate, what are we talking about?

Just a short re-cap: what is it again? The occupancy rate is the percentage that indicates the extent to which the available capacity is used. In other words: how many places are still available in your warehouse and many are in use? The higher the occupancy rate, the more efficient you work. But on the other hand, an occupancy rate that is too high means that your warehouse may be too small for your business. So what is the ideal occupancy rate?

Calculating the costs of a pallet place

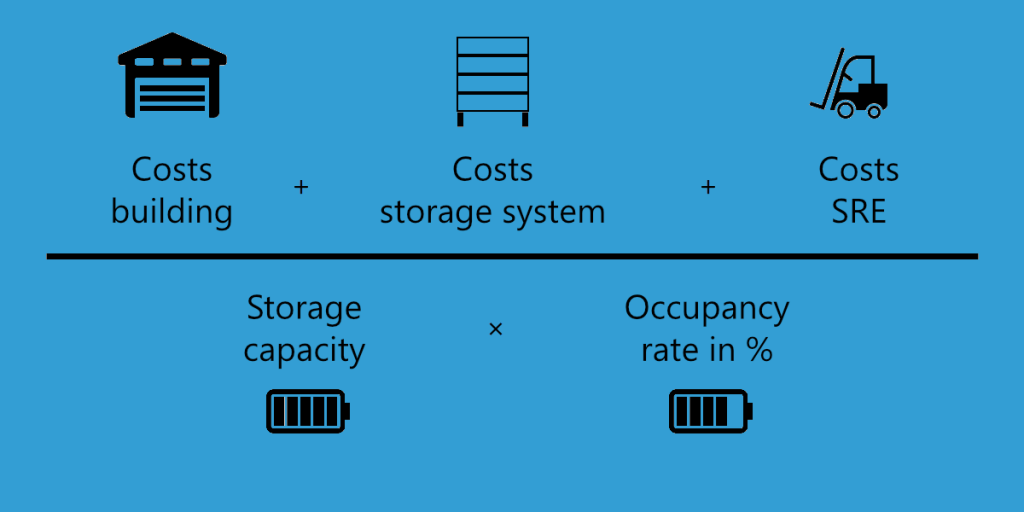

The price of storage places differs, of course, per distribution center. The more efficient you work, the lower the costs will be for you. And thus the higher the margins. Some variables are required to calculate the costs of one pallet location. Above the line you see the total relevant costs. SRE stands for storage and retrieval equipment. The number of used pallet places is shown under the line. So, the costs for a pallet place depend on the moment. The more capacity is in use, the cheaper the places are for you. With this formula you can also calculate the minimum occupancy needed to cover the costs; the breakeven point. From there you can determine to which occupancy rate you can still work productively within your warehouse.

What does this mean for me?

By gaining (visual) insight into the occupancy rate, you know to what extent your warehouse is efficient. Is a large part of your capacity unused? Then push a little bit harder to get extra assignments. Or try to reduce your costs through automation. Is your maximum often reached? Good job! Perhaps it is time to expand or organize the warehouse in another way. Data can also help you to chart the seasonal influences, so you can anticipate on them. The more knowledge you have, the more you can act substantiated.

Fourth industrial (r)evolution

As I mentioned at the beginning of this blog: revolution demands change. Those who do not (want to) change, do not participate anymore after a while. A tough pill to swallow, but a reality that has been proven each time throughout the history. Adaptability and behavioral change are of vital importance here. Invest in data analysis, implement this with all your processes and you will see that you will boost your efficiency.